Top Thrill Dragster

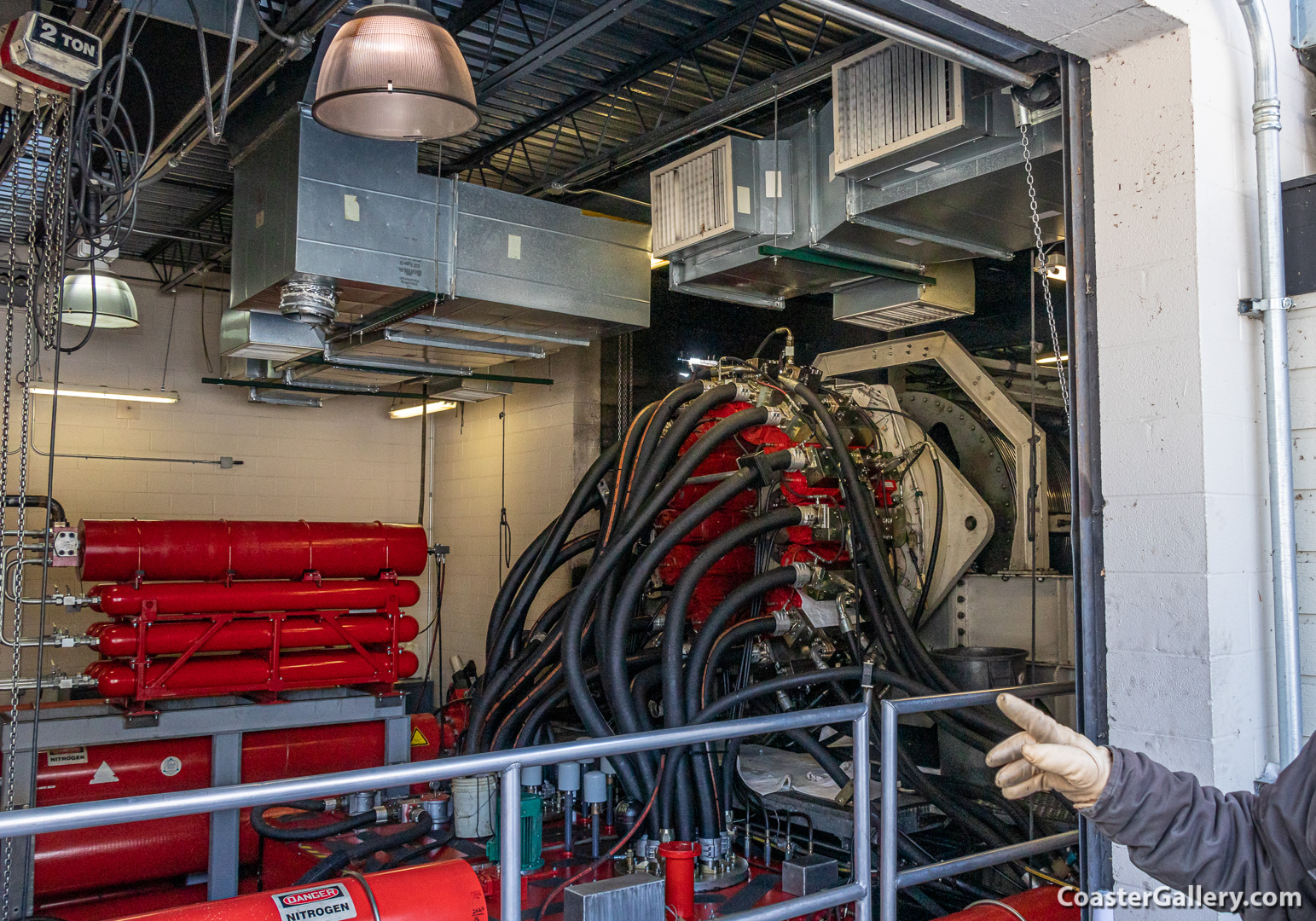

Here is a little behind-the-scenes look into the building that contains the hydraulic propulsion system. It sits at the end of the launch track. On the right border of this image, a little bit of the massive drum that houses the launch cables can be seen. This drum is located in the middle of the building. The equipment shown in this picture is all attached to one side of the drum. On the other side of the building, unseen in this image, is an identical set of equipment attached to the other side of the drum. For example, 16 red hydraulic motors are attached to this side of the drum. There are another 16 motors on the other side. The 32 motors are attached to gears that drive the large drum. It spins up to a little over 500 revolutions per minute, or about nine turns a second, during a launch.

Four subsystems are used to spin the cable drum, two of which are mounted in this half of the building, the other two are located in the opposite half of this building. Each subsystem is connected to eight hydraulic motors. The four subsystems are practically identical, so let me describe how one works... The system uses hydraulic fluid and nitrogen gas. The gas is compressible, but the fluid is not. The main component of each subsystem is a large accumulator, the large red pipes with "Danger Nitrogen" signs on them. It is a long tube with a movable piston placed inside. Hydraulic fluid is located on one side of the piston. In some accumulator applications, a weight or a spring is used to push against the piston to counteract the force of the fluid, but in Top Thrill Dragster's accumulators, nitrogen gas is used. To supplement the gas side of the accumulator, it is attached to several more bottles of compressed nitrogen. Even when the coaster is dormant, the nitrogen bottles and air side of the accumulator are pressurized to several times normal atmospheric pressure. Each of the four systems has its own 500-horsepower motor mounted below the equipment seen in this picture. The motor moves hydraulic oil into the fluid side of the accumulator. Since the liquid can't compress, it moves the piston and pushes the nitrogen back into the gas tanks. After 45 to 50 seconds of motor operation, the accumulator is full of hydraulic fluid while the nitrogen tanks are charged to about 4,600 pounds per square inch, or around 320 bar. When the command to launch the coaster is given, valves open to allow the fluid in the accumulator to pass to the eight hydraulic motors connected to each accumulator. The high-pressure nitrogen pushes against the accumulator's piston which forces the fluid out with extreme force! After passing through the motors, fluid drains into an unpressurized reservoir. You can see eight large hoses running from the motors and converging into one fixture on top of the reservoir. The motorized pump takes this fluid and returns it to the accumulator to be ready for the next ride cycle.

©2021 by Joel A. Rogers.